Web Designing

Expertise Overview

Software Application Development

Software Product Development

2/3 Tier Architecture

Multi Technology Services

Report for Mobile Devices

USFDA CFR11 Compliance

Audit Trail & Reports

Hardware Integration

Application Protection

SOP building

Application Validation

BCP & DRM Documentation

Product Areas

'Oil-Well'

SRP Maintenance Application for Oil Field Services Companies

(Conceptualised and developed by Inforcom Technologies)- Avoid Breakdown Penalties

- Breakdown Management

- PMS Task Planning

- SRP Life Cycle Management

- Work Allocation to Field Teams

- User Access Control

- Reports as per Govt. Formats

- Joint Survey Forms

- Daily Reports on Mobile*

- Google based Well Identification*

- Direct Reports to Head Office*

The Main Features of Oil-Well

THE ISSUE :

Companies offering Oil Field Services are on tight schedule to minimize the downtime of an oil field equipment. In the service contract for SRP (Sucker Rod Pump), the breakdown time should be within the permissible time frame. Any over time above this limit attracts very high penalties. The breakdown needs to be identified, attended and rectified in the minimum time in order to continue the pumping of Oil. The SRP also has a fixed maintenance cycle. Each SRP under contract needs to be serviced every 120 days. Any delay can

also be penalised. Further the paint work on SRPs also is time bound. The time frame being 3 years for painting on each

SRP. Companies handling very high numbers of SRPs in various Oil fields, required systematic and organised approach to

manage and document the daily tasks and complains if any. Further the team management is a critical task to maximize the

output per team.

The SRP also has a fixed maintenance cycle. Each SRP under contract needs to be serviced every 120 days. Any delay can

also be penalised. Further the paint work on SRPs also is time bound. The time frame being 3 years for painting on each

SRP. Companies handling very high numbers of SRPs in various Oil fields, required systematic and organised approach to

manage and document the daily tasks and complains if any. Further the team management is a critical task to maximize the

output per team.

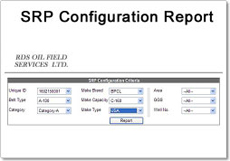

Technical Configuration Activity

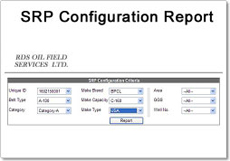

Oil-Well provides positioning of a well by configuring the Area, Location and GGS details. This grouping of the well will help in various routine processes as well as criteria based reports. Each of the Area, Location and GGS values can be set by the admin of this system. SRPs come in various makes and specifications. The next configuration is that of a SRP. Based on the options inserted by the system admin, the SRP can be categorised by the make, capacity, power source etc. including the belts and motor specifications.

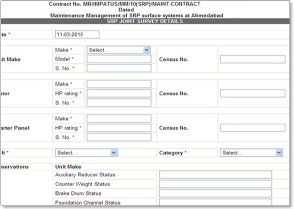

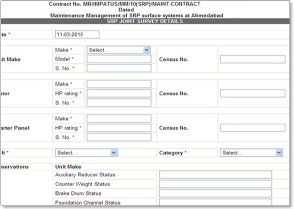

Joint Survey and Erection Process

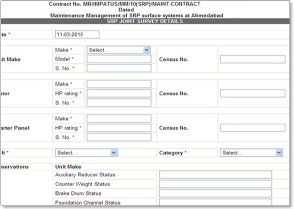

As per the Govt. Standard Compliance, a Joint Survey is carried out before intialising a SRP. Oil-Well offers the joint survey form. This includes make, module etc., census no. along with observations if any e.g. Aux Reducer Status, Counter Weight Status, Drum Status etc. (details below). The Print out is in the standard format as per the Govt. regulations. The same can be submitted to ONGC. Unique identification numbers are assigned to these SRP for future reference. The step by step SRP initialisation process is offered in the application. For each essential step, the related data entry is entered and stored for all future reporting purpose. All the activities can be referred and searched. In the life cycle control of a SRP, the first step is offered by Oil-Well, the first erection process with its related reports and life cycle commencement.

- Make, Model, Serial No., Belt info

- Census No.

- Auxiliary Reducer Status

- Counter Weight Status

- Brake Drum Status

- Foundation Channel Status

- Stroke Counter Status

- Belt Guard Status

- Samsong Post Ladder

- Motor Canopy Status

- Starter Panel Type

- ATS Status, Earth Leakage CB, Cyclic Timer

- Contactor, Capacitor & Fuse

SRP Life Cycle

Each SRP moves from well to well as per the production requirement and the capacity, as well as the condition of it. From the SRP errection onward all the stages are offered in Oil-Well.This includes:

- Installation on Well

- SRP Shift

- SRP Swap

- SRP Stand by

- SRP Discard.

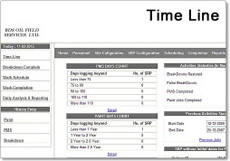

PMS (Planned Maintenance Service)

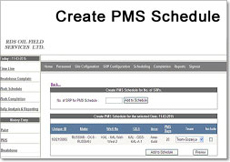

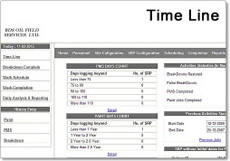

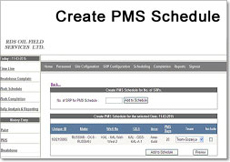

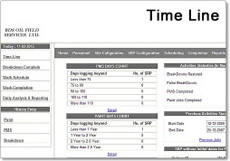

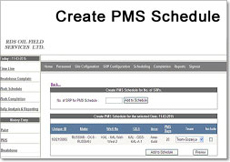

Oil-Well offers the important feature for Oil Fields Service - PMS – Planned Maintenance Service. It is essential to carry out a maintenance routine on a SRP in no longer than 120 days cycle. The SRPs under contract have different 120 cycle, occurring On any given day. This software shows the SRP to be managed in descending order of the day from the previous PMS. For the SRP, the one to finish 120 days will be on top, meaning it should be serviced at the earliest. This helps to generate the PMS schedule for a day or in advance also. The scheduled SRP will be out from the list and the next SRP shall come up in the list. This ensures that no SRP is missed from the list of servicing. The PMS task completed must be inserted in the system. These inputs shall generate the report for submission. Further analysis reports are also generated.Breakdown Maintenance

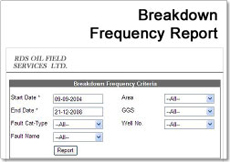

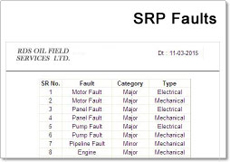

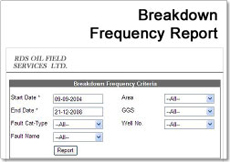

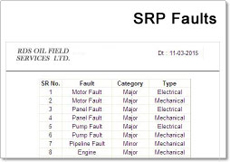

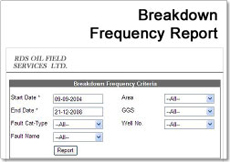

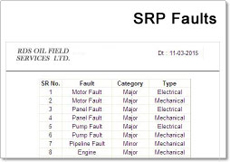

A Breakdown of a long duration can attract huge penalties. Oil-Well offers tool to manage the breakdowns. There are separate modules for recording the Breakdowns, Breakdown Rectification Schedule and Breakdown Completion. The possible faults for a SRP are inserted in the system to make the selection process easy. The fault complain entry is a simple process. By providing the SRP no., the fault Category, fault severity and details, it registers the fault in the system. The registered faults are listed by date and time. This list helps to create the schedule for a day with inclusion of visit to the well to attend the fault. The system assures the reporting for a visit. Completion reporting for a Breakdown is a critical task. This generates completion entries as well reports for Govt. submission. There are other reports also generated for breakdown history, frequency, SRP breakdown count, SRP performance etc. These reports offer valuable statistical analysis for various equipments performance and health status for its future usability plan.Scheduled Paint Work

The SRPs under contract have to painted once every 3 years. This routine if not maintained will attract penalties. The software lists the SRPs in order of the next immediate paint priority . This list helps the planner to schedule paint jobs. The completion of a paint job is required to be reported to the software. This eliminates the job from the list and further generates reports.Breakdown / PMS Scheduling

The scheduling is combination of Breakdown, PMS and Paint work. Breakdowns control a visit based on its criticality. Since a visit to the well is essential, many times PMS or Paint job can be handled in advance and save a visit to the site. This planning offers flexibility as well as efficiency for optimum utilization of resources along with the deadline management. The Breakdown, PMS and Paint jobs Planned can be assigned to various teams. Team wise daily Schedule can be printed. This offers task list for each team with the work for a day.The Output and Reports

There are two sets of reports offered: Compliance Reports for Submission at ONGC and Activity Analysis Reports for current Performance Tracking.The Reports to submit to ONGC are in the official format.

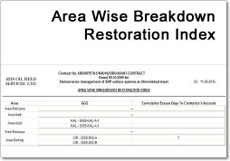

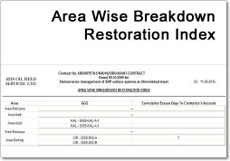

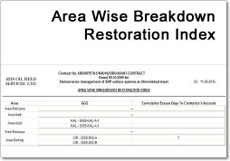

- Area wise Breakdown Restoration Index,

- Monthly Break down Statement,

- Breakdown Summery Report,

- Status Report SRP (annexure A, B)

- PMS Paint Monitoring Reports

- PMS Paint Work Report

The Analysis Reports are

- Breakdown Frequency Report

- False Call Breakdown Frequency Report

- Joint Survey Report

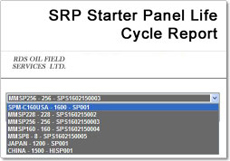

- SRP Life Cycle Report

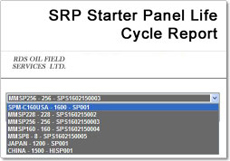

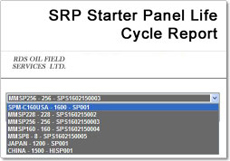

- Motor and Starter Panel Life Cycle Report

- Last dates for Breakdown

- All dates for SRPs

- Fault wise breakdown

- Theft Reports

- SRP Shifting Report

- PMS Paint for SRPs

- Last PMS for SRP

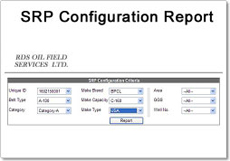

- SRP Configuration Report

- Software System Design and Development

- Software Products Development with Management tools

- Client Specific Application Development

- Web Applications and Website Development

- Data Processing and Application Protection

- IT Consulting

'Oil-Well'

SRP Maintenance Application for Oil Field Services Companies

(Conceptualised and developed by Inforcom Technologies)- Avoid Breakdown Penalties

- Breakdown Management

- PMS Task Planning

- SRP Life Cycle Management

- Work Allocation to Field Teams

- User Access Control

- Reports as per Govt. Formats

- Joint Survey Forms

- Daily Reports on Mobile*

- Google based Well Identification*

- Direct Reports to Head Office*

The Main Features of Oil-Well

THE ISSUE :

Companies offering Oil Field Services are on tight schedule to minimize the downtime of an oil field equipment. In the service contract for SRP (Sucker Rod Pump), the breakdown time should be within the permissible time frame. Any over time above this limit attracts very high penalties. The breakdown needs to be identified, attended and rectified in the minimum time in order to continue the pumping of Oil. The SRP also has a fixed maintenance cycle. Each SRP under contract needs to be serviced every 120 days. Any delay can

also be penalised. Further the paint work on SRPs also is time bound. The time frame being 3 years for painting on each

SRP. Companies handling very high numbers of SRPs in various Oil fields, required systematic and organised approach to

manage and document the daily tasks and complains if any. Further the team management is a critical task to maximize the

output per team.

The SRP also has a fixed maintenance cycle. Each SRP under contract needs to be serviced every 120 days. Any delay can

also be penalised. Further the paint work on SRPs also is time bound. The time frame being 3 years for painting on each

SRP. Companies handling very high numbers of SRPs in various Oil fields, required systematic and organised approach to

manage and document the daily tasks and complains if any. Further the team management is a critical task to maximize the

output per team.

Technical Configuration Activity

Oil-Well provides positioning of a well by configuring the Area, Location and GGS details. This grouping of the well will help in various routine processes as well as criteria based reports. Each of the Area, Location and GGS values can be set by the admin of this system. SRPs come in various makes and specifications. The next configuration is that of a SRP. Based on the options inserted by the system admin, the SRP can be categorised by the make, capacity, power source etc. including the belts and motor specifications.

Joint Survey and Erection Process

As per the Govt. Standard Compliance, a Joint Survey is carried out before intialising a SRP. Oil-Well offers the joint survey form. This includes make, module etc., census no. along with observations if any e.g. Aux Reducer Status, Counter Weight Status, Drum Status etc. (details below). The Print out is in the standard format as per the Govt. regulations. The same can be submitted to ONGC. Unique identification numbers are assigned to these SRP for future reference. The step by step SRP initialisation process is offered in the application. For each essential step, the related data entry is entered and stored for all future reporting purpose. All the activities can be referred and searched. In the life cycle control of a SRP, the first step is offered by Oil-Well, the first erection process with its related reports and life cycle commencement.

- Make, Model, Serial No., Belt info

- Census No.

- Auxiliary Reducer Status

- Counter Weight Status

- Brake Drum Status

- Foundation Channel Status

- Stroke Counter Status

- Belt Guard Status

- Samsong Post Ladder

- Motor Canopy Status

- Starter Panel Type

- ATS Status, Earth Leakage CB, Cyclic Timer

- Contactor, Capacitor & Fuse

SRP Life Cycle

Each SRP moves from well to well as per the production requirement and the capacity, as well as the condition of it. From the SRP errection onward all the stages are offered in Oil-Well.This includes:

- Installation on Well

- SRP Shift

- SRP Swap

- SRP Stand by

- SRP Discard.

PMS (Planned Maintenance Service)

Oil-Well offers the important feature for Oil Fields Service - PMS – Planned Maintenance Service. It is essential to carry out a maintenance routine on a SRP in no longer than 120 days cycle. The SRPs under contract have different 120 cycle, occurring On any given day. This software shows the SRP to be managed in descending order of the day from the previous PMS. For the SRP, the one to finish 120 days will be on top, meaning it should be serviced at the earliest. This helps to generate the PMS schedule for a day or in advance also. The scheduled SRP will be out from the list and the next SRP shall come up in the list. This ensures that no SRP is missed from the list of servicing. The PMS task completed must be inserted in the system. These inputs shall generate the report for submission. Further analysis reports are also generated.Breakdown Maintenance

A Breakdown of a long duration can attract huge penalties. Oil-Well offers tool to manage the breakdowns. There are separate modules for recording the Breakdowns, Breakdown Rectification Schedule and Breakdown Completion. The possible faults for a SRP are inserted in the system to make the selection process easy. The fault complain entry is a simple process. By providing the SRP no., the fault Category, fault severity and details, it registers the fault in the system. The registered faults are listed by date and time. This list helps to create the schedule for a day with inclusion of visit to the well to attend the fault. The system assures the reporting for a visit. Completion reporting for a Breakdown is a critical task. This generates completion entries as well reports for Govt. submission. There are other reports also generated for breakdown history, frequency, SRP breakdown count, SRP performance etc. These reports offer valuable statistical analysis for various equipments performance and health status for its future usability plan.Scheduled Paint Work

The SRPs under contract have to painted once every 3 years. This routine if not maintained will attract penalties. The software lists the SRPs in order of the next immediate paint priority . This list helps the planner to schedule paint jobs. The completion of a paint job is required to be reported to the software. This eliminates the job from the list and further generates reports.Breakdown / PMS Scheduling

The scheduling is combination of Breakdown, PMS and Paint work. Breakdowns control a visit based on its criticality. Since a visit to the well is essential, many times PMS or Paint job can be handled in advance and save a visit to the site. This planning offers flexibility as well as efficiency for optimum utilization of resources along with the deadline management. The Breakdown, PMS and Paint jobs Planned can be assigned to various teams. Team wise daily Schedule can be printed. This offers task list for each team with the work for a day.The Output and Reports

There are two sets of reports offered: Compliance Reports for Submission at ONGC and Activity Analysis Reports for current Performance Tracking.The Reports to submit to ONGC are in the official format.

- Area wise Breakdown Restoration Index,

- Monthly Break down Statement,

- Breakdown Summery Report,

- Status Report SRP (annexure A, B)

- PMS Paint Monitoring Reports

- PMS Paint Work Report

The Analysis Reports are

- Breakdown Frequency Report

- False Call Breakdown Frequency Report

- Joint Survey Report

- SRP Life Cycle Report

- Motor and Starter Panel Life Cycle Report

- Last dates for Breakdown

- All dates for SRPs

- Fault wise breakdown

- Theft Reports

- SRP Shifting Report

- PMS Paint for SRPs

- Last PMS for SRP

- SRP Configuration Report

- Software System Design and Development

- Software Products Development with Management tools

- Client Specific Application Development

- Web Applications and Website Development

- Data Processing and Application Protection

- IT Consulting

'Oil-Well'

SRP Maintenance Application for Oil Field Services Companies

(Conceptualised and developed by Inforcom Technologies)- Avoid Breakdown Penalties

- Breakdown Management

- PMS Task Planning

- SRP Life Cycle Management

- Work Allocation to Field Teams

- User Access Control

- Reports as per Govt. Formats

- Joint Survey Forms

- Daily Reports on Mobile*

- Google based Well Identification*

- Direct Reports to Head Office*

The Main Features of Oil-Well

THE ISSUE :

Companies offering Oil Field Services are on tight schedule to minimize the downtime of an oil field equipment. In the service contract for SRP (Sucker Rod Pump), the breakdown time should be within the permissible time frame. Any over time above this limit attracts very high penalties. The breakdown needs to be identified, attended and rectified in the minimum time in order to continue the pumping of Oil. The SRP also has a fixed maintenance cycle. Each SRP under contract needs to be serviced every 120 days. Any delay can

also be penalised. Further the paint work on SRPs also is time bound. The time frame being 3 years for painting on each

SRP. Companies handling very high numbers of SRPs in various Oil fields, required systematic and organised approach to

manage and document the daily tasks and complains if any. Further the team management is a critical task to maximize the

output per team.

The SRP also has a fixed maintenance cycle. Each SRP under contract needs to be serviced every 120 days. Any delay can

also be penalised. Further the paint work on SRPs also is time bound. The time frame being 3 years for painting on each

SRP. Companies handling very high numbers of SRPs in various Oil fields, required systematic and organised approach to

manage and document the daily tasks and complains if any. Further the team management is a critical task to maximize the

output per team.

Technical Configuration Activity

Oil-Well provides positioning of a well by configuring the Area, Location and GGS details. This grouping of the well will help in various routine processes as well as criteria based reports. Each of the Area, Location and GGS values can be set by the admin of this system. SRPs come in various makes and specifications. The next configuration is that of a SRP. Based on the options inserted by the system admin, the SRP can be categorised by the make, capacity, power source etc. including the belts and motor specifications.

Joint Survey and Erection Process

As per the Govt. Standard Compliance, a Joint Survey is carried out before intialising a SRP. Oil-Well offers the joint survey form. This includes make, module etc., census no. along with observations if any e.g. Aux Reducer Status, Counter Weight Status, Drum Status etc. (details below). The Print out is in the standard format as per the Govt. regulations. The same can be submitted to ONGC. Unique identification numbers are assigned to these SRP for future reference. The step by step SRP initialisation process is offered in the application. For each essential step, the related data entry is entered and stored for all future reporting purpose. All the activities can be referred and searched. In the life cycle control of a SRP, the first step is offered by Oil-Well, the first erection process with its related reports and life cycle commencement.

- Make, Model, Serial No., Belt info

- Census No.

- Auxiliary Reducer Status

- Counter Weight Status

- Brake Drum Status

- Foundation Channel Status

- Stroke Counter Status

- Belt Guard Status

- Samsong Post Ladder

- Motor Canopy Status

- Starter Panel Type

- ATS Status, Earth Leakage CB, Cyclic Timer

- Contactor, Capacitor & Fuse

SRP Life Cycle

Each SRP moves from well to well as per the production requirement and the capacity, as well as the condition of it. From the SRP errection onward all the stages are offered in Oil-Well.This includes:

- Installation on Well

- SRP Shift

- SRP Swap

- SRP Stand by

- SRP Discard.

PMS (Planned Maintenance Service)

Oil-Well offers the important feature for Oil Fields Service - PMS – Planned Maintenance Service. It is essential to carry out a maintenance routine on a SRP in no longer than 120 days cycle. The SRPs under contract have different 120 cycle, occurring On any given day. This software shows the SRP to be managed in descending order of the day from the previous PMS. For the SRP, the one to finish 120 days will be on top, meaning it should be serviced at the earliest. This helps to generate the PMS schedule for a day or in advance also. The scheduled SRP will be out from the list and the next SRP shall come up in the list. This ensures that no SRP is missed from the list of servicing. The PMS task completed must be inserted in the system. These inputs shall generate the report for submission. Further analysis reports are also generated.Breakdown Maintenance

A Breakdown of a long duration can attract huge penalties. Oil-Well offers tool to manage the breakdowns. There are separate modules for recording the Breakdowns, Breakdown Rectification Schedule and Breakdown Completion. The possible faults for a SRP are inserted in the system to make the selection process easy. The fault complain entry is a simple process. By providing the SRP no., the fault Category, fault severity and details, it registers the fault in the system. The registered faults are listed by date and time. This list helps to create the schedule for a day with inclusion of visit to the well to attend the fault. The system assures the reporting for a visit. Completion reporting for a Breakdown is a critical task. This generates completion entries as well reports for Govt. submission. There are other reports also generated for breakdown history, frequency, SRP breakdown count, SRP performance etc. These reports offer valuable statistical analysis for various equipments performance and health status for its future usability plan.Scheduled Paint Work

The SRPs under contract have to painted once every 3 years. This routine if not maintained will attract penalties. The software lists the SRPs in order of the next immediate paint priority . This list helps the planner to schedule paint jobs. The completion of a paint job is required to be reported to the software. This eliminates the job from the list and further generates reports.Breakdown / PMS Scheduling

The scheduling is combination of Breakdown, PMS and Paint work. Breakdowns control a visit based on its criticality. Since a visit to the well is essential, many times PMS or Paint job can be handled in advance and save a visit to the site. This planning offers flexibility as well as efficiency for optimum utilization of resources along with the deadline management. The Breakdown, PMS and Paint jobs Planned can be assigned to various teams. Team wise daily Schedule can be printed. This offers task list for each team with the work for a day.The Output and Reports

There are two sets of reports offered: Compliance Reports for Submission at ONGC and Activity Analysis Reports for current Performance Tracking.The Reports to submit to ONGC are in the official format.

- Area wise Breakdown Restoration Index,

- Monthly Break down Statement,

- Breakdown Summery Report,

- Status Report SRP (annexure A, B)

- PMS Paint Monitoring Reports

- PMS Paint Work Report

The Analysis Reports are

- Breakdown Frequency Report

- False Call Breakdown Frequency Report

- Joint Survey Report

- SRP Life Cycle Report

- Motor and Starter Panel Life Cycle Report

- Last dates for Breakdown

- All dates for SRPs

- Fault wise breakdown

- Theft Reports

- SRP Shifting Report

- PMS Paint for SRPs

- Last PMS for SRP

- SRP Configuration Report

- Software System Design and Development

- Software Products Development with Management tools

- Client Specific Application Development

- Web Applications and Website Development

- Data Processing and Application Protection

- IT Consulting